Profile:

- Continuous Learning/Sharing

- Interdisciplinary Problem-solving

- High Emotional Intelligence

- Willing to accept new challenge

Skills:

- Cad: Pro/E, AutoCad

- Integrated Design

- Networking

- Programming: Python / Go / MATLAB

- Linux / Cloud Services

Experiences:

Project Manager / Technical Director

Ash Cloud Co., Ltd Shenzhen, China, 2013-2023

Ash Cloud Co., Ltd Shenzhen, China, 2013-2023

System Install Engineer

ASML Linkou, 2012-2013

ASML Linkou, 2012-2013

Industrial Designer

Mintstar Products Design, 2003-2012

Mintstar Products Design, 2003-2012

Achievements:

Ash Cloud

Public Relations

Results:

- Produced successful case study videos featured on Apple's official websites worldwide, expanding the recognition of Ash Cloud. Link to the successful case on Apple.com ->

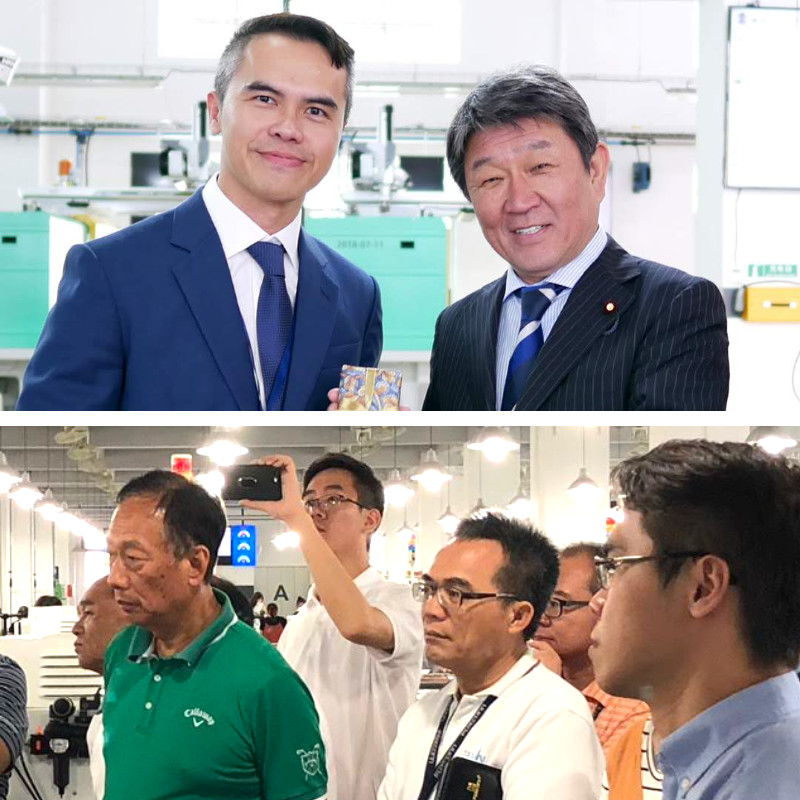

- Organized factory open days, attracting visits with Japan's former Foreign Minister, Motegi Toshimitsu (茂木 敏充), and the founder of Foxconn, Terry Gou(郭台銘).

Tasks

- Promote the success story of Ash Cloud on Apple's official website

- Organize and host the factory open day

Establishing a new plastic production and molding division

Tasks:

- Acquire knowledge in new fields: plastic injection molding, CNC machining.

- Technically evaluate and procure various high-value processing equipments.

- Plan factory sites, technology, and various specifications for water, electricity.. etc.

- Resolve various production and technical issues.

- Expand production scale.

Results:

- Successfully established smooth mass production, exporting products and molds to Europe and the United States.

Rebuilding the AGV (Automated Guided Vehicle) System

Tasks:

- Reactivating the AGV with no document

- Reverse engineering to understand the functionality of each component

- Integration of hardware with different voltages and communication protocols, including motors, sensors, Lidar, electric rollers, etc

- Writing Python control programs

- Designing and making circuit boards

Results:

- Transitioning from closed-source to open-source Python + Raspberry Pi, reducing the maintenance costs for subsequent personnel.

- Transferring AGV System to Ming-Chi University for educational purposes and enabling Kang Hong Logistics to continue developing derivative models.

Creating an Industrial IoT System

Tasks:

- Designing IoT hardware and software.

- Collecting data from machines, applying AI machine learning to analyze status to infer operational efficiency.

- Collecting data on water, electricity, gas consumption, as well as environmental factors such as temperature and humidity.

- Using the time-series database influxDB to store production data.

- Implementing 3D printing for small-batch design and production.

Results:

- IoT devices that can transmit equipment status without the need for intrusion into the machinery.

- Easy setup, accessible even to non-specialists.

Establishing a Production Dashboard System

Tasks:

- Installing displays and Raspberry Pi computers in the production site.

- Configuring the Raspberry Pi to display a specific webpage upon startup.

- Designing necessary data charts for display on the server for various site dashboards.

Results:

- The dashboard enables the visibility of latent issues in the production site, facilitating real-time detection and resolution, thereby enhancing production efficiency and reducing waste.

Unlocking AWS cloud servers, optimizing and adding new features

Tasks

- Emergency assignment to handle 16 Linux servers with no documentation and locked keys, to prevent the halt of the production management system.

- Understanding the original architecture and interdependencies from backup images, addressing issues related to startup sequences, and replacing keys for a reboot.

- Optimizing system architecture, rewriting components, and implementing Docker.

Results:

- Planning a new authority structure, establishing an internal documentation wiki to prevent a similar disaster from recurring.

- Improving optimization, enhancing system stability and fault tolerance, resulting in a reduction in monthly AWS costs from $CNY 20,000 to $7,000 (a 65% decrease).

Lean Production: Improving Work Efficiency

Tasks:

- Introducing item aluminum profiles for manufacturing auxiliary tools.

- Quick and easy adjustments.

- Knowledge transfer to all mechanics so they can build the tools.

- Eco-friendly as aluminum profiles can be disassembled and reused.

Results:

- The aluminum profiles can be flexibly applied, enabling the production site to create and adjust the necessary tools according to requirements by themselves.

ASML:

Build and install Yieldstar

Machine father of YieldStar, install several machines in TSMC Hsinchu and Tainan.

Educations:

- Industrial Design, National Taipei University of Technology, Bachelor's degree, 1999-2002

- Industrial Design, Mingchi Institute of Technology, 1991-1996

Languages:

- Mandarin: Fluent

- English: Professional Working Proficiency

Certifications:

- Project Management Professional (2023)

- TOEIC: score 920 (2012)

- Patents: IoT Sensors (pending)

Contact:

- Taiwan mobile: +886 (936)675245

- China mobile: +86 13825211801

- E-mail: chen.zard@gmail.com

- Web: https://alex.guguman.club

- Linkedin: https://www.linkedin.com/in/alexchen1976/